Our process

Digital Grid Systems design, assemble, Produce and test electronic components & PCB assemblies for OEMS. Digital Grid Systems may provide a variety of Manufacturing services including design, assembly & testing. DGS may be contracted at various points in the manufacturing process. The manufacturing involves different levels of automation depending on the company & project.

Concept

Product design involves open communication between the client and DGS. Most of the time, DGS will ask the client/customer for a concept and they work off of it. A lot of back and forth with suggestions and specifications until the final design is created. In

DGS we have an expert team of graphic designers to take care of design tasks.

Research and development

DGS have laboratories designed for product testing and failure investigation. The engineers who conduct these tests will also take advantage of these as a research and development process for future electronic designs related to the current model.

Prototype

Once the design is ready, it now enters the product development stage with the main objective of having a product prototype at the end of the line. After noting down all of the details and specifications for the electronic product, DGS will work on the project and complete it as conceived. Extensive research and brainstorming will be done before they integrate into actual manufacturing process to keep risks at a minimum and avoid wasting time and money. The product prototype should be a perfect replica of the design template including specs and details.

Testing

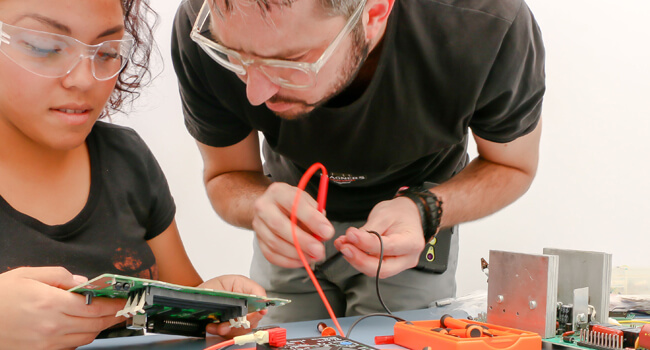

An electronic prototype which serves as the product replica is going to be the tested in its different facets in multiple times. The goal is to ensure the product meets safety precautions and quality standards with its full functionality. DGS have laboratories designed for product testing and failure investigation. The engineers who conduct these tests will also take advantage of these as a research and development process for future electronic designs related to the current model.

Advanced testing procedures include optical inspection which automatically analyze the PCB for issues and defects on the computer. Broken traces, patches, etching issues and improper hole locations are easily detected through automated optical inspection. Another important type of testing process is environmental testing wherein the product is exposed to its intended environment and check if it reacts to the

environment’s temperature, humidity, air pressure among other factors to test its durability and resistance.

There are several more testing procedures such as functional testing, in-circuit testing, x-ray testing and a lot more depending on the nature of the product. All of these testing procedures will be performed on the product as part of the quality control

program and ensure it is in its top form for mass production.

Manufacturing

Electronic manufacturing is usually divided on to two major areas with mass production capabilities: PCB manufacturing and electronic product manufacturing.

1. PCB Manufacturing

There are electronics manufacturing companies who specialize in ODM PCB manufacturing . PCB manufacturing is the task which involves the most electronic knowledge since the printed circuit board houses all of the electrical components, circuits and processors. Electronic manufacturing companies who specialize in ODM PCB manufacturing are most likely staffed with electrical engineers and electronics experts.

2. Electronics Product Manufacturing

3.Specialty Production

Quality Testing

Once you’re done with designing and testing, it’s time to distribute it. But, again, before you start with distribution, run a few final tests to ensure that your customers don’t get faulty products. This will ensure that your product’s or company’s brand image does not suffer.

Repairs and returns of the PCBs are also a part of the electronics manufacturing process, because you have to deal with faulty electronics that you have produced and distributed.

It doesn’t mean that you have knowingly supplied the faulty product, it’s just the nature of electronics products. They may stop working anytime, and whoever made them has to fix the fault.

End Product

The consumer electronics industry is growing rapidly and so are the challenges associated with it. Even minor changes in the rules and regulations, guidelines, and preferences from the client

or public can affect the whole manufacturing process, not to mention the rapid advancements in technology.

To remain up-to-date with all advances that occur in the design, production, and testing processes, here in DGS we implement regular changes. DGS we bring new technology and products to the market.